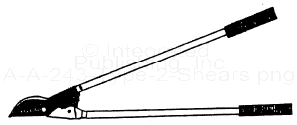

Figure 2 - Type II Shears

3.5 Operation. The pruning shears shall be designed for two hand operation. The closing of the shears shall be limited by means of either integral or external stop(s).

3.6 Finish. The cutting blade and hook shall have a permanently applied corrosion resistant finish. The finish shall be chrome plating, black oxide, or a teflon-type (polytetrafluoroethylene) coating to prevent corrosion and debris build-up. The sharpened edge of the blade shall not be coated.

3.7 Performance. The shears shall be capable of cleanly cutting one at a time, fifteen branches of green hardwood of the specified diameter (cutting capacity) l The size 1 shears shall be capable of cutting branches 1-1/2 inches (3.8 cm) in diameter. The size 2 shears shall be capable of cutting branches 1-5/8 inches (4.1 cm) in diameter. The size 3 shears shall be capable of cutting branches 2 inches (5.1 cm) in diameter. Each cut shall be made in one “bite*’ without splintering the wood or breaking, bending, or showing signs of distortion or damage to any part of the shears. The shears shall show no evidence of vegetation or debris build-up between the blade and hook. Additionally, the shears shall show no distortion of the cutting head, loosening, or bending of the handles or other signs of damage after the cutting operation.

3.8 Identification marking. The shears shall be marked with the manufacturer’s name or trademark. The use of an adhesive--backed label shall be acceptable.

3.9 Workmanship. The shears shall be free from defects which will impair the serviceability, durability or appearance of the shears. The shears shall be smoothly finished, true to shape, and show no evidence of misalignment. The operation or handling of the shears shall not be injurious to personnel.

3.10 Metric products. Products manufactured to metric dimensions will be considered on an equal basis with those manufactured using inch-pound units, providing they fall within tolerances specified and all other requirements of this document are met. If a product is manufactured to metric dimensions and those dimensions exceed the tolerances specified in the inch-pound units, a request should be made to the contracting officer to determine if the product is acceptable.

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business